Who is this program for?

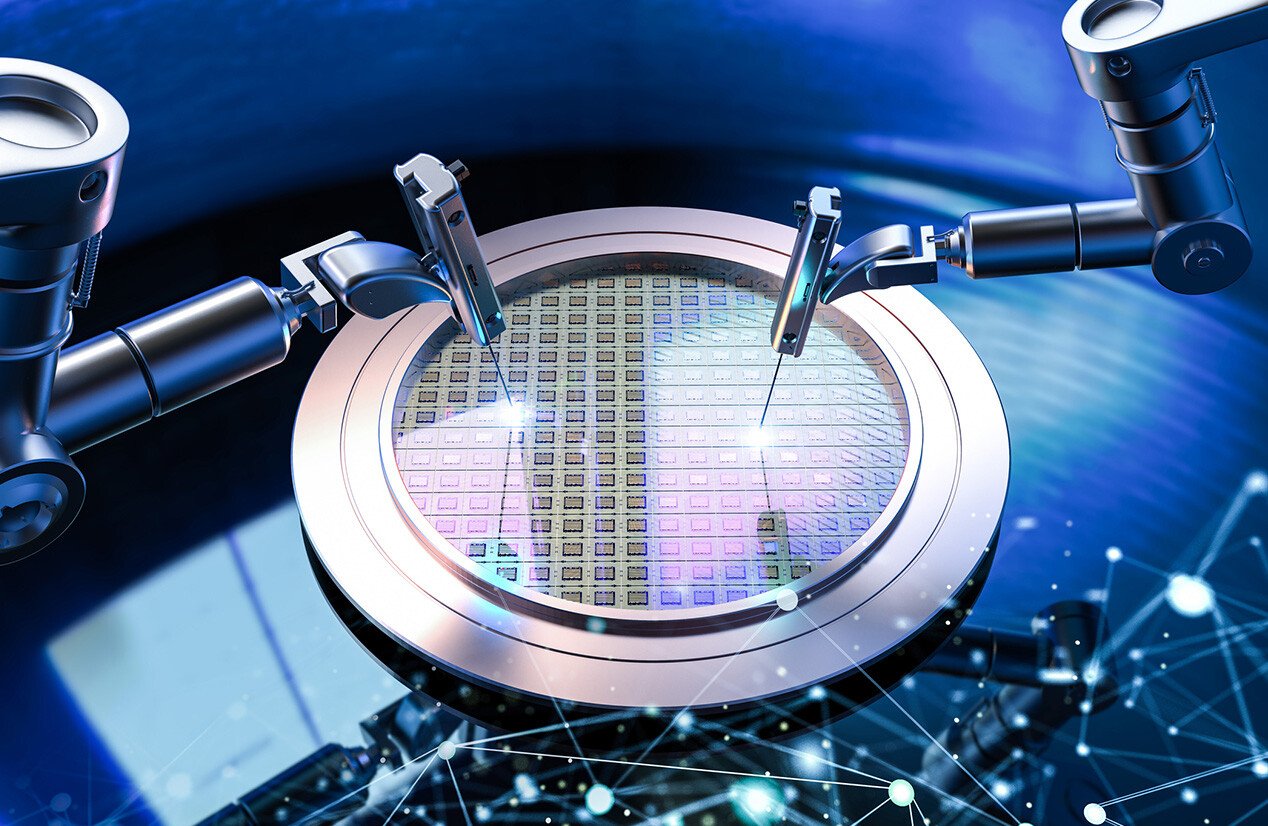

With this credential, learners will establish a foundational understanding of about basic principles of semiconductors. Starting with the process of converting raw materials such as silica sand into pure silicon, the program then provides an overview of the major processes in wafer fabrication. The program moves on to understanding basic semiconductor testing and the packaging process.

The program provides an overview of the semiconductor industry as it is poised for significant growth, driven by technological advancements and increasing demand across various sectors. This program will help learners understand the present days challenges and innovations in semiconductor industry.

At the end of this credential, you will be able to:

- Explain energy bands and bandgaps.

- Differentiate between conductors, semiconductors, and insulators.

- Describe the steps involved in the extraction and purification of silicon.

- Explain the crystal growth methods such as Czochralski and Float Zone processes.

- Describe the role of packaging in protecting and interconnecting semiconductor devices.

- Apply techniques for measuring resistance in semiconductors using appropriate instrumentation.

- Conduct reliability testing to assess the longevity and robustness of semiconductor products.

- Analyze the key sectors driving demand.

- Summarize the future prospects and potential industry leaders.

- Understand the cost pressures in the semiconductor industry.

- Visualize the future trends and opportunities.

Representative Job Titles

-

Semiconductor Field Service Engineer/Technician

-

Facilities Maintenance Technician

-

Semiconductor Equipment Technician

-

Preventative Maintenance (PM) Technician

-

Technical Specialist

-

Semiconductor Design Engineer

-

Semiconductor Reliability Engineer

-

Smart Factory Automation Specialists

Why Choose a Career in Smart Manufacturing?

The Importance of Semiconductors

Course Overview

There is a massive shortage of technical workers in the U.S who know how to install and operate specialized equipment in a semiconductor-grade facility. Skills of electricians, pipefitters and welders; technical engineers, maintenance personnel and smart factory automation specialists; and graduate electrical engineers to design chips and the tools and manufacturing processes that make the chips are in high demand.

Semiconductor chip companies consider expediting hiring diverse skills for both building and automating their manufacturing facilities and designing chips and tools.

Production and engineering jobs make up more than half of the domestic semiconductor workforce, but the industry also employs workers in management, business and financial operations, mathematics, sales, administrative support, maintenance, transportation, and more.

This credential covers the topics of:

- Module 1: Foundations of Semiconductors

- Module 2: From Sand to Silicon

- Module 3: Semiconductor Device Fabrication Flow

- Module 4: Testing and Packaging in Semiconductors

- Module 5: Semiconductor Global Impact & Industry Giants

- Module 6: Challenges and Innovations in Semiconductor Industries

This credential includes videos, quizzes, simulations, and case studies with the goal of providing students with a strong overview of the semiconductor industry.

This program will equip learners with the following work competencies:

- Basic understanding on semiconductor device physics.

- Understanding how silicon wafers are made from raw materials.

- Skills on various semiconductor process. These are the skill needed to be semiconductor process technician or engineer.

- Basic testing and packaging methods in semiconductors.

- Understanding the present days challenges and innovations in semiconductor industry.

Pricing

Pay All At Once

Installment Plan - Over four installments

Still Have Questions?

This is a 9-week program that will require about 5 to 6 hours of dedicated time per week.

No. Micro-credentials are not transferrable for credit. These are skills-based training programs that differ from a traditional college course.

No, there are no assignment deadlines. There is, however, a prescribed pace for timely completion as learners will have a set number of weeks to complete the credential.

Micro-credentials are self-paced and do not require the learner to attend class at a certain time each week. Learners should expect to spend 5-6 hours per week engaging with the course at their own pace. Select weeks will have optional webinars featuring industry experts.

Students will receive a certificate of completion.

Please feel free to use any of these options to reach out to us. We would love to hear from you!

- Call us at 888-603-0027

- Email us at CSUAdmissions@focusedusolutions.com

- Fill out the form at the bottom of this page

- Use the chat to connect with one of our counselors

Want to learn more?